Text & media

On the Mark: Implementing OSHA's Floor Marking Standards

Floor marking is often overlooked. However, it plays a crucial role in maintaining a safe and organized environment. Employees need to understand the significance of adhering to the osha floor marking guide to prevent accidents and streamline operations. This blog post will delve into the importance of implementing these standards, providing practical insights on color codes, placement guidelines, and maintenance procedures. By grasping these concepts, employees can contribute to a safer work environment while enhancing efficiency.

Understanding OSHA's Floor Marking Guidelines

Importance of OSHA's Standards

OSHA's floor marking standards play a crucial role in ensuring workplace safety. By clearly defining walkways, storage areas, and hazardous zones, these guidelines help prevent accidents and injuries.

Implementing OSHA's floor marking standards can significantly reduce the risk of slips, trips, and falls in the workplace. This is especially important in environments where employees are exposed to various hazards such as wet floors, uneven surfaces, or cluttered pathways.

Compliance with OSHA's floor marking guidelines also fosters a culture of safety awareness among employees. Clear and consistent visual cues enable workers to identify potential dangers and navigate the workspace with confidence.

Practical Application of OSHA Guidelines

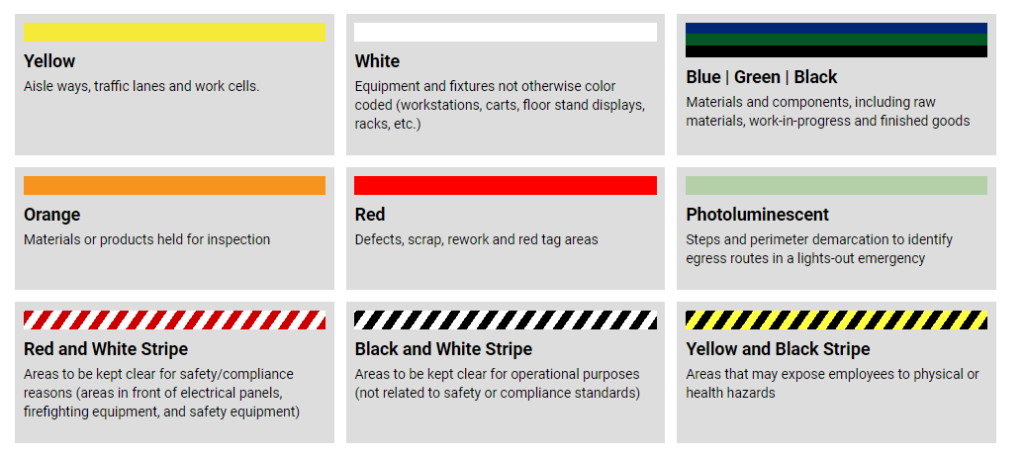

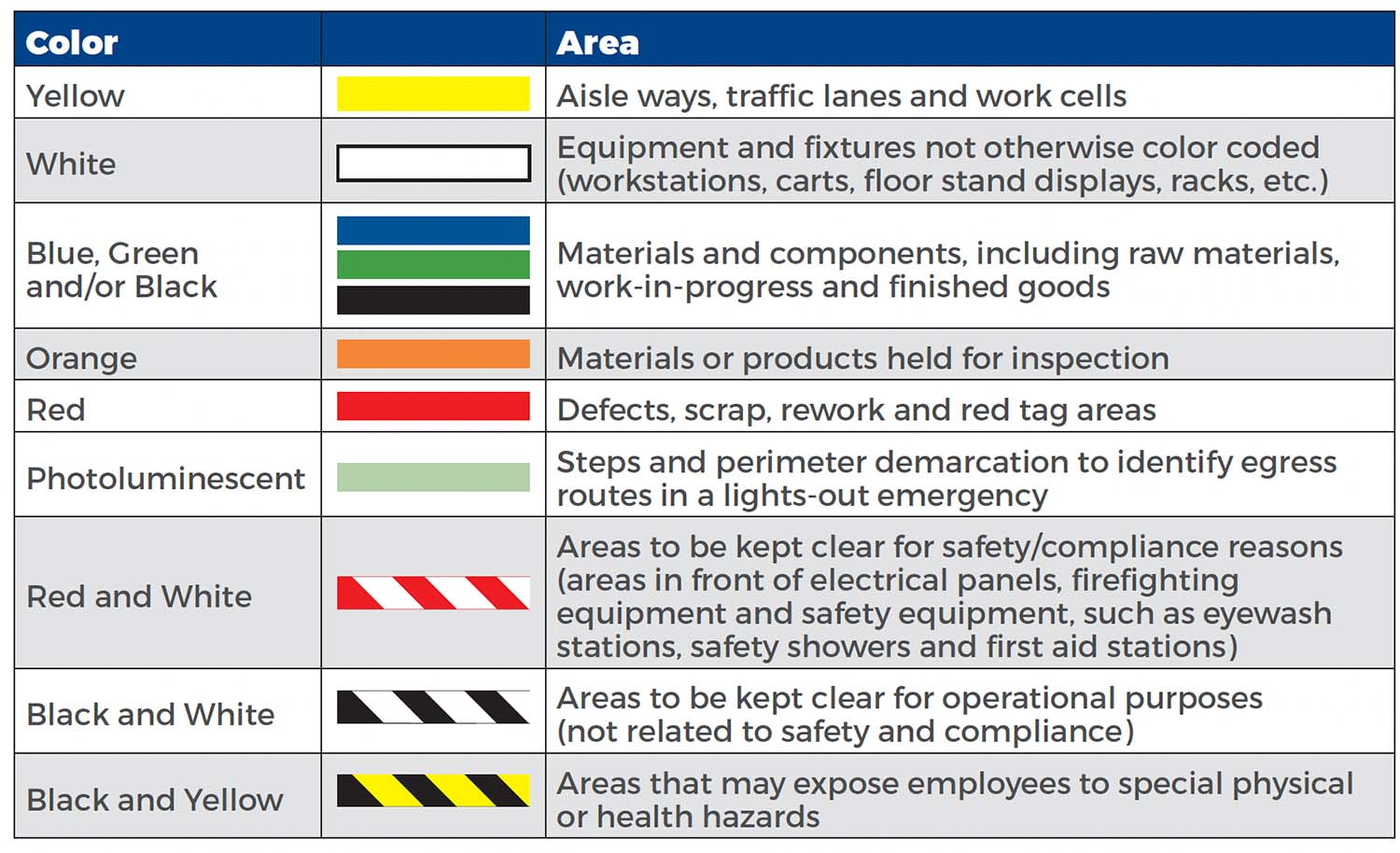

When implementing OSHA's floor marking standards, it’s essential to use durable materials that can withstand heavy foot traffic and industrial equipment. Color coding plays a key role in conveying specific information about different areas within the facility.

For instance:

Using yellow tape for aisles and walkways

Employing red tape to mark off-limits or hazardous zones

Utilizing green tape for first aid stations or emergency equipment locations

Color Coding for Safety and Compliance

Importance of Color Coding

Color coding is a crucial aspect of implementing OSHA's floor marking standards. It helps employees easily identify safety hazards, locate equipment, and understand specific areas within the facility. For instance, using yellow to mark aisles where traffic from forklifts or other heavy machinery is common can alert employees to proceed with caution.

Implementing color-coded floor markings also aids in maintaining compliance with OSHA regulations. By adhering to the standard color scheme recommended by OSHA, businesses can ensure that their facilities meet safety requirements and avoid potential fines or penalties.

Color coding plays a vital role in enhancing workplace safety by reducing accidents and promoting an organized work environment. When employees are consistently exposed to color-coded floor markings that signify different safety protocols or instructions, they become more accustomed to recognizing and following these guidelines as part of their daily routine.

Best Practices for Implementation

When implementing OSHA's floor marking standards, it's essential for employers to educate their workforce about the meaning of each color used in the facility. This includes providing training on what each color signifies in terms of safety precautions or designations within the workspace.

Furthermore, creating clear visual cues through consistent use of colors throughout the facility ensures that all employees - including new hires - can quickly grasp important information regarding safety procedures and navigational guidance.

Organizational Benefits of Effective Floor Marking

Enhanced Safety

Effective floor marking greatly enhances workplace safety. It helps employees and visitors identify hazardous areas, emergency exits, and safe pathways. For instance, using bright yellow or red floor markings to indicate forklift zones can prevent accidents by alerting everyone about potential dangers.

Floor markings also play a crucial role in preventing slips, trips, and falls. By clearly demarcating walkways and caution areas with highly visible tape or paint, organizations reduce the risk of accidents. This not only protects employees from injuries but also minimizes the company's liability for workplace incidents.

Improved Efficiency

Efficient floor marking contributes to streamlined operations within an organization. Clear demarcation of storage areas ensures that items are stored in designated locations, making it easier for workers to find what they need quickly. This reduces time wastage and boosts productivity.

Moreover, organized workspaces facilitate smoother workflow management as employees can easily navigate through different sections without confusion or delay. In production facilities, color-coded floor markings help workers identify where raw materials should be placed versus finished products awaiting shipment.

Implementing the 5S Floor Marking Standard

Importance of Consistency

Consistency in floor marking is crucial for maintaining a safe and organized work environment. When employees encounter consistent floor markings, they can quickly identify designated areas for storage, traffic lanes, and hazardous zones. This consistency reduces the risk of accidents and promotes operational efficiency. For example, using the same color to signify safety hazards throughout the facility ensures that all employees recognize these areas instantly.

Maintaining uniformity in floor marking also supports the principles of 5S methodology - Sort, Set in Order, Shine, Standardize, and Sustain. By adhering to standardized floor markings as part of their daily routines, employees actively contribute to workplace organization and cleanliness. Moreover, it reinforces a culture where everyone is responsible for upholding safety standards.

Consistent floor marking also aids in regulatory compliance with OSHA standards by providing clear visual cues regarding specific safety protocols or designations within an industrial setting.

Effective Communication

Implementing OSHA's floor marking standards facilitates effective communication across all levels of an organization. The use of universally understood symbols and colors helps convey important information without language barriers. For instance, utilizing yellow lines to delineate work cells effectively communicates boundaries without relying on written instructions.

Furthermore, consistent implementation allows new hires or visitors to quickly grasp essential safety information simply by observing floor markings. This enhances overall workplace transparency while promoting a culture centered around employee well-being.

Enhancing Industrial Wayfinding and Traffic Routes

Visual Communication

Visual communication through floor marking is an effective way to convey information in industrial settings. Color-coded floor markings, as per OSHA standards, can indicate different safety zones, traffic routes, or hazardous areas. For instance, a bright yellow line might signify a walkway for employees, while red could denote a fire exit route.

Using geometric shapes in floor marking also aids in conveying specific instructions. A circle might indicate where materials should be placed, while squares could highlight the location of equipment storage. This visual language helps employees quickly understand their surroundings and navigate accordingly.

Safety Compliance

Implementing OSHA's floor marking standards ensures that industrial facilities are compliant with safety regulations. By clearly delineating work areas and traffic paths using OSHA-approved colors, companies mitigate the risk of accidents and injuries. Adhering to these guidelines not only promotes employee safety but also demonstrates an organization's commitment to maintaining a secure work environment.

A well-executed system of floor markings enhances efficiency and productivity by streamlining workflows and reducing confusion about designated areas within the facility.

Adhering to International Fire Code and ANSI Standards

Importance of Compliance

Compliance with OSHA's floor marking standards is crucial for ensuring workplace safety. It helps prevent accidents, promotes efficient traffic flow, and enhances emergency preparedness. By adhering to the International Fire Code and ANSI standards, employees can create a safer work environment while also staying in line with legal requirements.

Implementing the recommended color codes for floor markings as per OSHA guidelines ensures that employees are aware of potential hazards, safe pathways, and restricted areas within the facility. This compliance supports a proactive approach to safety management by providing clear visual cues that aid in accident prevention.

Clear Communication Through Visual Cues

Following OSHA's floor marking standards not only fosters workplace safety but also facilitates more organized operations. For instance, using yellow tape or paint to mark areas where caution should be exercised alerts employees to proceed carefully. Similarly, implementing red markings for fire equipment storage areas ensures quick identification during emergencies.

Tips for Precision and Maintenance in Floor Marking

Regular Inspections

Employees should conduct regular inspections of the floor markings to ensure they are still clearly visible and intact. This involves checking for any signs of wear, such as peeling or fading, and promptly addressing any issues. For instance, if a section of the floor marking has started to fade due to heavy traffic, it should be repainted or replaced to maintain visibility and compliance with OSHA standards.

It's crucial for employees to understand that regular inspections not only help maintain safety but also prevent potential hazards caused by unclear or damaged floor markings. These routine checks can be scheduled at specific intervals, depending on the level of foot traffic in the area where the markings are located.

Use of High-Quality Materials

When implementing OSHA's floor marking standards, using high-quality materials is paramount. Employees should opt for durable tapes, paints, or other marking solutions that can withstand heavy machinery use and continuous foot traffic. High-quality materials contribute significantly to longevity and effectiveness in maintaining clear demarcation within facilities.

For example:

Utilizing industrial-grade floor tape designed with strong adhesives

Applying epoxy-based paint specifically formulated for high-traffic areas

Installing robust floor decals made from long-lasting vinyl material

Closing Thoughts

The implementation of OSHA's floor marking standards is not just about compliance; it's a fundamental aspect of creating a safe and efficient workplace. By understanding the guidelines, utilizing color coding effectively, and adhering to industry standards, employees can significantly enhance safety, organization, and overall operational efficiency. Precision and maintenance are crucial for sustaining these benefits over time, ensuring that floor markings remain clear, accurate, and impactful.

As employees strive to implement these practices, they should remember that safety is a continuous journey rather than a final destination. Regular assessments, updates, and employee training are essential for maintaining an environment where everyone can thrive. By staying proactive and committed to these principles, employees can create a workplace where safety is ingrained in every aspect of their operations.