Text & media

Comprehensive OSHA Floor Marking Guide: Understanding and Implementing Color Code Standards for Enhanced Safety and Compliance in the Workplace

In any workplace, safety should always be a top priority. One crucial aspect of ensuring a safe working environment is proper floor marking. The Occupational Safety and Health Administration (OSHA) has established comprehensive guidelines for floor marking safety, providing employers with valuable insights on how to implement effective measures.

Implementing proper floor marking not only helps prevent accidents and injuries but also promotes efficiency and organization within the workplace. By clearly indicating hazardous areas, emergency exits, pathways, and storage zones, employees can navigate their surroundings with ease and confidence.

Adhering to OSHA's floor marking standards offers numerous benefits for both employers and employees. It minimizes the risk of slips, trips, and falls by creating clear visual cues that guide individuals safely throughout the facility. It streamlines operations by optimizing traffic flow and preventing confusion or miscommunication.

By following this guide on OSHA's floor marking standards, you can enhance workplace safety while improving overall productivity. Stay tuned for our upcoming posts where we will delve deeper into specific guidelines provided by OSHA to ensure your workplace remains secure.

Understanding OSHA Standards for Floor Marking

In order to maintain a safe working environment, it is crucial for employers and employees to understand and comply with the Occupational Safety and Health Administration (OSHA) standards for floor marking. These regulations provide guidelines on color coding and labeling in the workplace, ensuring that hazards are clearly identified, and employees can navigate their surroundings safely.

Explanation of OSHA Regulations Related to Floor Marking

OSHA has established specific guidelines regarding floor marking standards to promote safety in various industries. These regulations outline the use of colors, labels, signs, and symbols to communicate important information about potential hazards or safety precautions within a facility. By adhering to these regulations, companies can minimize accidents, prevent injuries, and create a more secure work environment.

OSHA provides guidance on color coding for different purposes. For example:

Yellow is commonly used to mark areas where caution is required or where physical hazards may be present.

Red indicates fire protection equipment or emergency stop controls.

Green typically signifies safety equipment or first aid stations.

Blue is often used for informational signs or indicating equipment locations.

By using consistent colors throughout a facility, employees can quickly recognize potential dangers or locate essential safety resources. This helps reduce confusion and promotes efficiency in emergency situations.

Key Requirements for Color Coding and Labeling in the Workplace

Compliance with OSHA standards involves implementing effective color coding systems that meet specific requirements. Key requirements include:

Consistency: Colors should be used consistently across all areas of the workplace so that employees can easily interpret their meanings without confusion.

Visibility: Floor markings must be clearly visible even under varying lighting conditions. High-quality materials should be used to ensure longevity and legibility.

Durability: The chosen floor marking materials should withstand heavy foot traffic, industrial machinery movement, cleaning processes, and other environmental factors without fading or peeling.

Standardization: It is important to follow industry standards when selecting colors and symbols for floor markings. This ensures that employees, contractors, and visitors can easily understand the messages conveyed by the markings regardless of their familiarity with a specific facility.

By meeting these requirements, companies can effectively communicate safety information through floor markings, reducing the risk of accidents and injuries in the workplace.

Compliance with OSHA Standards Ensures a Safe Working Environment

Complying with OSHA standards for floor marking is not only a legal requirement but also essential for maintaining a safe working environment. Here are some benefits of adhering to these regulations:

Improved Safety Awareness: Clear and consistent floor markings increase employees' awareness of potential hazards, helping them make informed decisions to prevent accidents.

Enhanced Efficiency: Well-planned floor marking systems enable smooth traffic flow, efficient material storage, and streamlined operations.

Reduced Risk of Accidents: By clearly identifying hazardous areas or equipment locations, floor markings help minimize the risk of slips, trips, falls, collisions, and other workplace accidents.

Regulatory Compliance: Complying with OSHA standards demonstrates an organization's commitment to employee safety and helps avoid penalties or fines associated with non-compliance.

Safety Color Code for Physical Hazards

In order to ensure safety in the workplace, it is crucial to have a consistent system for marking physical hazards. This is where the safety color code comes into play. By using specific colors to identify different types of hazards, employees can quickly recognize potential dangers and take appropriate precautions.

Identification and Meaning of Different Colors Used for Physical Hazards

The safety color code assigns specific meanings to different colors, allowing workers to easily identify and understand the nature of a hazard. Here are some common colors used for physical hazards:

Yellow: This color is typically associated with caution or warning. It is used to mark areas where there may be a potential risk or where extra attention should be paid. For example, yellow floor markings might indicate areas with tripping hazards or low clearance.

Red: Red is often used to signify danger or stop. It alerts individuals to immediate hazards that could cause serious harm or injury. For instance, red floor markings might indicate fire extinguishers or emergency shut-off switches.

Orange: Orange is commonly used for warning purposes as well. It indicates potential dangers that may not be as severe as those marked by red but still require caution. An example of orange floor markings could be areas near machinery with moving parts.

Green: Green typically represents safety or safe conditions. It can be used to mark emergency exits, first aid stations, or other areas where individuals can find assistance in case of an emergency.

Examples of Common Physical Hazards and Their Corresponding Color Codes

To better understand how the safety color code works, let's look at some examples of physical hazards and their corresponding color codes:

Electrical Hazards: These pose a risk of electric shock or electrocution. They are often marked with yellow and black stripes on equipment or walls.

Chemical Hazards: Chemicals that are toxic, flammable, or corrosive should be clearly identified. Red labels or signs are commonly used to indicate the presence of such hazards.

Fall Hazards: Areas with a risk of falling, such as stairways or elevated platforms, can be marked with yellow floor tape or paint to draw attention and prevent accidents.

Fire Hazards: Fire extinguishers, fire alarms, and areas where flammable materials are stored should be marked with red signage or floor markings.

Importance of Consistent Color Coding to Prevent Accidents and Injuries

Consistent color coding is essential for maintaining a safe work environment. It helps employees quickly identify potential hazards and take appropriate action to avoid accidents and injuries. Here's why it matters:

Increased Awareness: Clear color-coded markings increase awareness among employees, making them more cautious and alert in hazardous areas.

Efficient Communication: The use of standardized colors ensures that everyone understands the meaning behind each marking, regardless of language barriers or individual interpretations.

Prevention of Accidents: By clearly identifying physical hazards through color coding, employers can significantly reduce the risk of accidents and injuries in the workplace.

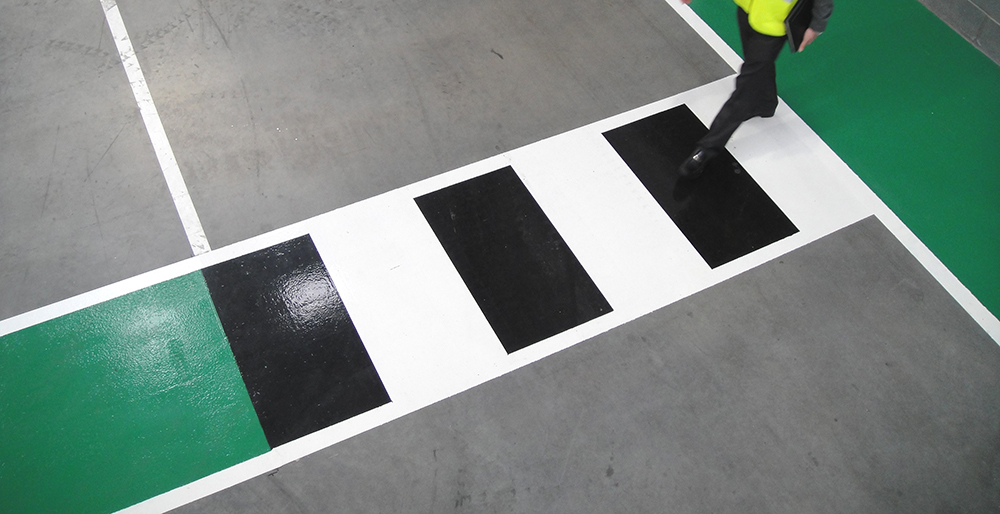

Implementing Floor Marking for Warehouse Safety

In warehouse environments, floor marking plays a crucial role in enhancing safety and preventing accidents. By strategically implementing floor marking systems, warehouses can create clear pathways, identify hazardous areas, and improve overall organization. Let's explore the best practices for planning and implementing effective floor marking systems in warehouses.

Enhancing Safety with Floor Marking

Floor markings serve as visual cues that guide employees and visitors through the warehouse while keeping them safe. Here's how they enhance safety:

Clear Pathways: Properly marked pathways ensure smooth traffic flow within the warehouse, reducing the risk of collisions between pedestrians and vehicles.

Hazard Identification: Floor markings can be used to highlight hazardous areas such as loading docks, electrical panels, or areas prone to spills.

Organization: By designating specific areas for storage or equipment placement through floor markings, warehouses can maintain orderliness and prevent clutter.

Emergency Preparedness: Clearly marked evacuation routes and emergency exits help employees navigate quickly during critical situations.

Best Practices for Planning and Implementation

To ensure an effective floor marking system in your warehouse, consider these best practices:

Pre-Planning: Before starting a floor marking project, conduct a thorough inspection of the facility to identify potential hazards or bottlenecks that need attention.

Color Selection: Choose colors that comply with OSHA guidelines while considering their visibility against the background flooring color.

Standardization: Maintain consistency throughout the warehouse by using uniform symbols, shapes, and text on all floor markings.

Durability: Select high-quality floor marking materials that can withstand heavy traffic, machinery movement, cleaning agents, and other environmental factors.

Maintenance Plan: Regularly inspect and touch up any damaged or faded markings to ensure continued effectiveness.

Case Studies: Successful Warehouse Safety Improvements

Let's take a look at two case studies that showcase how floor marking has contributed to significant safety improvements in warehouses:

Case Study 1: ABC Warehouse implemented a comprehensive floor marking system that included clear pathways, designated storage areas, and hazard identification markings. As a result, they experienced a 30% decrease in accidents related to collisions and improved overall efficiency.

Case Study 2: XYZ Warehouse used color-coded floor markings to differentiate between different types of materials stored in their facility. This not only enhanced organization but also reduced the time spent searching for specific items by 40%.

By implementing these best practices and learning from successful case studies, warehouses can create safer environments for their employees while improving overall efficiency.

Floor marking is an essential aspect of warehouse safety, providing visual cues that guide employees and visitors through the facility. By following best practices and drawing inspiration from successful case studies, warehouses can ensure effective implementation of floor marking systems. So, let's get started on creating a safer environment within your warehouse!

Choosing Between Floor Marking Paint and Tape

One crucial decision you'll need to make is whether to use floor marking paint or tape. Each option has its pros and cons, so it's essential to consider various factors before making a choice.

Pros and Cons of Using Paint or Tape for Floor Marking Applications

Both floor marking paint and tape have their advantages and disadvantages. Let's take a closer look at them:

Floor Marking Paint:

Pros:

Durability: Floor marking paint is known for its long-lasting nature. It can withstand heavy traffic, including forklifts and other machinery.

Versatility: Paint allows for customization, as it can be easily applied in different colors and patterns.

Permanent: Once applied, floor marking paint becomes a permanent part of the flooring surface.

Cons:

Time-consuming application process: Painting requires proper preparation of the surface, including cleaning and drying before application. It also takes time for the paint to dry completely.

Professional assistance may be needed: For larger areas or complex designs, hiring a painting contractor might be necessary to ensure an even and professional finish.

Floor Marking Tape:

Pros:

Easy installation: Applying floor marking tape is relatively quick and straightforward. It doesn't require any special skills or equipment.

Flexibility: Unlike paint, tape can be easily removed or repositioned if needed without leaving residue behind.

Immediate usability: Once applied, floor marking tape is ready for immediate use without any drying time required.

Cons:

Durability concerns: While some types of tape are highly durable, others may not withstand heavy traffic or extreme conditions as well as paint does.

Limited customization options: Tape typically comes in standard colors and patterns, limiting your ability to create unique designs.

Factors to Consider When Deciding Between Paint or Tape

Several factors should influence your decision when choosing between floor marking paint and tape:

Durability: Consider the level of traffic in your facility and whether the markings will be exposed to harsh conditions or heavy machinery.

Ease of installation: Evaluate the time, effort, and resources required for application. Determine if you have the necessary expertise or if professional assistance is needed.

Customization options: Think about whether you require specific colors, patterns, or symbols for your floor markings.

Maintenance requirements: Consider how easy it is to clean and maintain each option over time.

Recommendations Based on Specific Needs, Budget, and Maintenance Requirements

Ultimately, the choice between floor marking paint and tape depends on your specific needs, budget constraints, and maintenance requirements. Here are some recommendations based on different scenarios:

If durability is a top priority and customization options are essential:

Floor marking paint would be the ideal choice as it offers long-lasting durability along with customizable designs.

If ease of installation and flexibility are crucial factors:

Floor marking tape provides quick installation without any drying time required. It also allows for easy removal or repositioning.

Remember to weigh all the pros and cons carefully before making a decision that suits your warehouse safety needs best.

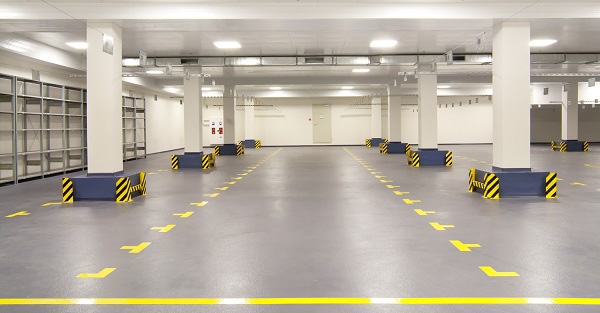

Optimizing Workflow Efficiency with Aisle Ways and Traffic Lanes

To maximize productivity and streamline operations in the workplace, it is crucial to have well-designed aisle ways and traffic lanes. These designated pathways play a significant role in improving workflow efficiency by ensuring smooth movement of people, equipment, and materials. By following guidelines for designing effective aisle ways and traffic lanes, businesses can enhance productivity and reduce the risk of accidents or delays.

The Role of Aisle Ways and Traffic Lanes in Improving Workflow Efficiency

Aisle ways and traffic lanes act as clear pathways that guide employees, machinery, and products throughout the workspace. They create organized routes that allow for seamless movement from one area to another. By implementing these designated passages, businesses can achieve the following benefits:

Efficient Flow: Well-planned aisles ensure a logical flow of work within the workplace. They help prevent congestion or bottlenecks by providing dedicated spaces for movement.

Enhanced Safety: Properly marked traffic lanes promote safety by separating pedestrians from vehicles or heavy machinery. This reduces the risk of accidents and minimizes potential injuries.

Improved Communication: Clearly defined aisles and lanes enable effective communication between workers as they navigate through shared spaces. It facilitates collaboration, coordination, and quick response times.

Optimized Space Utilization: A well-organized layout with efficient aisle ways allows businesses to make optimal use of available space. It enables easy access to workstations, storage areas, docks, or production lines.

Guidelines on Designing Effective Aisle Ways and Traffic Lanes

When designing aisle ways and traffic lanes in your workplace, consider these best practices:

Width: Determine the appropriate width based on your specific needs – considering factors such as foot traffic volume or equipment dimensions.

Clear Markings: Use floor marking tape or paint to clearly delineate aisles and lanes on the floor. Ensure the markings are highly visible and resistant to wear and tear.

Consistency: Maintain consistent aisle width throughout your facility to avoid confusion or inconsistencies in traffic flow.

Obstacle-Free: Keep aisles free from clutter, obstacles, or equipment that may hinder movement or pose safety hazards.

Directional Signage: Install clear directional signage at intersections or junctions to guide employees and visitors through the correct pathways.

Examples of How Proper Layout Can Enhance Productivity in Different Industries

The benefits of well-designed aisle ways and traffic lanes can be observed across various industries:

In a warehouse setting, clearly marked aisles allow for efficient movement of goods, reducing the time spent searching for products and optimizing picking processes.

In manufacturing facilities, properly designated traffic lanes ensure smooth material flow between workstations, minimizing disruptions and delays in production.

In healthcare environments, well-organized corridors enable quick access to medical supplies and equipment, enhancing patient care delivery.

By following these guidelines and tailoring them to suit specific industry requirements, businesses can create an optimized workspace that maximizes workflow efficiency while prioritizing safety.

Material Storage Areas: Utilizing White Lines for Equipment Storage Zones

Clear markings play a crucial role. One effective way to designate specific equipment storage zones is by utilizing white lines. These lines not only provide visual guidance but also offer several benefits for efficient organization.

Importance of Clearly Marked Equipment Storage Zones

Clearly marked equipment storage zones are essential for maintaining an organized and safe working environment. Here's why they are important:

Efficient Workflow: By designating specific areas for storing equipment, raw materials, machinery, and finished goods, you can streamline workflow processes. Employees can easily locate the required items without wasting time searching through cluttered spaces.

Safety Measures: Properly marked storage zones help prevent accidents and injuries in the workplace. When all items have designated spaces, there is less chance of tripping over misplaced objects or colliding with machinery.

Inventory Management: Clear markings enable accurate inventory management by providing a visual representation of available space and capacity in each zone. This helps prevent overstocking or understocking of materials.

Benefits of Using White Lines to Designate Specific Areas

White lines serve as an effective tool for creating boundaries and visually separating different storage zones within a facility. Here are some benefits of using white lines:

Visibility: White lines stand out against most flooring surfaces, making them highly visible even from a distance. This ensures that employees can easily identify the boundaries of each equipment storage zone.

Flexibility: Unlike permanent fixtures such as walls or partitions, white lines offer flexibility in modifying or reorganizing the layout as per changing needs or seasonal requirements without any major construction work.

Cost-Effective Solution: Compared to installing physical barriers or separate enclosures for each zone, using white lines is a cost-effective solution that provides clear demarcation while minimizing expenses.

Tips on Organizing Material Storage Areas Effectively

To make the most of equipment storage zones and white lines, consider the following tips:

Zone Planning: Analyze your facility's layout and workflow requirements to determine the optimal placement of different zones. Categorize items based on frequency of use, accessibility, or any specific safety considerations.

Standardized Labeling: Implement a standardized labeling system for containers, shelves, and racks within each zone. This ensures consistency and ease in locating items, reducing errors and confusion.

Regular Maintenance: Regularly inspect and maintain the white lines to ensure their visibility remains intact. Over time, these lines may fade due to foot traffic or cleaning processes. Touch up or repaint them as necessary.

Employee Training: Provide training to employees regarding the importance of maintaining organized storage areas and how to adhere to designated zones. Encourage them to report any issues or suggestions for improvement.

By utilizing white lines effectively in material storage areas, you can optimize workflow efficiency, enhance safety measures, and improve inventory management within warehouses and facilities.

Key Takeaways from OSHA Floor Marking Guide

Summary of the OSHA Floor Marking Guide

The OSHA floor marking guide provides essential guidelines for maintaining a safe and organized workplace. It covers various aspects such as material storage, aisle marking, hazard identification, and more. The guide emphasizes the importance of clear and consistent floor markings to prevent accidents, promote efficiency, and comply with safety regulations.

Significance of Complying with OSHA Guidelines

Complying with OSHA's floor marking guidelines is crucial for several reasons. Firstly, it helps create a safe working environment by reducing the risk of accidents and injuries. Clear floor markings help employees navigate through busy areas, identify hazards promptly, and maintain proper spacing between equipment and materials.

Secondly, adhering to these guidelines ensures compliance with legal requirements. Failure to comply with OSHA standards can result in penalties, fines, or even legal action. By following the recommended practices outlined in the guide, businesses demonstrate their commitment to providing a safe workplace for their employees.

Lastly, complying with OSHA guidelines promotes operational efficiency. Properly marked floors improve workflow by guiding employees to designated areas for material storage or equipment placement. This reduces confusion and minimizes time wasted searching for items or determining appropriate pathways.

Implementing Proper Floor Marking Practices

To implement proper floor marking practices based on the OSHA guide, consider the following steps:

Evaluate your workspace: Assess your facility layout and identify areas that require floor markings such as aisles, walkways, hazardous zones, or material storage areas.

Choose appropriate colors: Select colors that align with industry standards and effectively communicate different meanings (e.g., yellow for caution/hazards or green for safety/first aid).

Determine width and placement: Follow OSHA's recommendations regarding line width based on traffic volume in each area.

Use clear signage: Utilize signs alongside floor markings to provide additional information or warnings.

Regular maintenance: Ensure that floor markings are well-maintained, visible, and not faded. Replace worn-out markings promptly to avoid confusion.

By implementing these practices, businesses can create a safer and more organized workplace environment while complying with OSHA regulations.

Conclusion: Key Takeaways from the OSHA Floor Marking Guide

Congratulations! You've now gained a comprehensive understanding of the OSHA Floor Marking Guide and how it can greatly enhance safety in your workplace. By implementing the safety color code for physical hazards, you can effectively communicate potential dangers to employees and visitors, reducing the risk of accidents. Whether you choose floor marking paint or tape, ensure its durability and visibility to maximize its effectiveness. Optimizing workflow efficiency through well-defined aisle ways and traffic lanes will streamline operations and prevent congestion. Lastly, utilizing white lines for equipment storage zones in material storage areas will help maintain order and prevent unnecessary damage.

Now that you're equipped with this knowledge, it's time to take action! Evaluate your current floor marking system against OSHA standards, identify any gaps or improvements needed, and implement the necessary changes. Remember, safety should always be a top priority in any workplace environment. By investing in proper floor marking techniques, you'll not only create a safer work environment but also boost productivity and efficiency.

FAQs

Can I use any colors for floor markings?

Floor markings should adhere to the safety color code specified by OSHA. These colors are standardized to convey specific messages related to hazards in the workplace. It is crucial to follow these guidelines to ensure clear communication of potential dangers.

How often should I repaint or replace floor markings?

The frequency of repainting or replacing floor markings depends on various factors such as foot traffic, machinery movement, cleaning processes, and environmental conditions. Regular inspections should be conducted to assess their condition and determine when maintenance or replacement is necessary.

Can I use temporary floor tape instead of permanent paint?

Temporary floor tape can be used in certain situations where flexibility is required or when regular changes are expected. However, permanent paint provides long-term durability and visibility that may be more suitable for high-traffic areas or areas with heavy machinery.

Are there any specific regulations for floor markings in warehouses?

While OSHA provides general guidelines for floor marking, specific regulations for warehouses may vary depending on the industry and location. It is essential to consult local regulations and industry standards to ensure compliance with all applicable requirements.

How can I ensure employees understand the meaning of different floor markings?

Proper training and education are key to ensuring employees understand the meaning of different floor markings. Conduct regular safety briefings, provide visual aids, and clearly communicate the significance of each color or symbol used in your workplace's floor marking system.