Text & media

An Introduction to TIMWOOD - The 7 Wastes of Lean

Taiichi Ohno (father of the Toyota Production System) developed TIMWOOD , a lean framework. It focuses on seven wastes: Transport, Inventory, Motion, Waiting, Overproduction, Overprocessing and Defects.

Identifying waste is an essential part of a successful business and can help you achieve your goals faster. It can be difficult to identify waste, especially if it isn't your first time to lean.

Improving User Experiences Through Eliminating Wastes in Business Processes

Glossary TIMWOOD, or the 7 Wastes of Lean, is a powerful framework created by Toyota to help organizations identify and eliminate waste in their business processes. By using the seven wastes in your process, you can improve productivity, profitability, and reduce costs, ultimately enhancing user experiences.

To start, it's crucial to understand the basics of wastes and how they relate to your organization. For instance, transportation of materials or components is considered a waste as it doesn't add value to the final product or service. Overproduction of inventory not required immediately is also a common waste that can lead to unnecessary costs.

To reduce waste, creating visual boards that highlight the seven main wastes can help you make informed decisions about how to allocate your resources and energy. This approach allows you to communicate better with your employees about the changes that will be beneficial to them and the company, ultimately making your organization a better place for your employees to do their best work.

What does TIMWOOD mean?

Taiichi Ohno (father of Toyota Production System) introduced TIMWOOD, a Lean framework. He first identified seven different types of waste in his manufacturing process (known as Muda), and they are: Transportation, Inventory, Motion, Waiting, Overproduction, Over Processing and Defects.

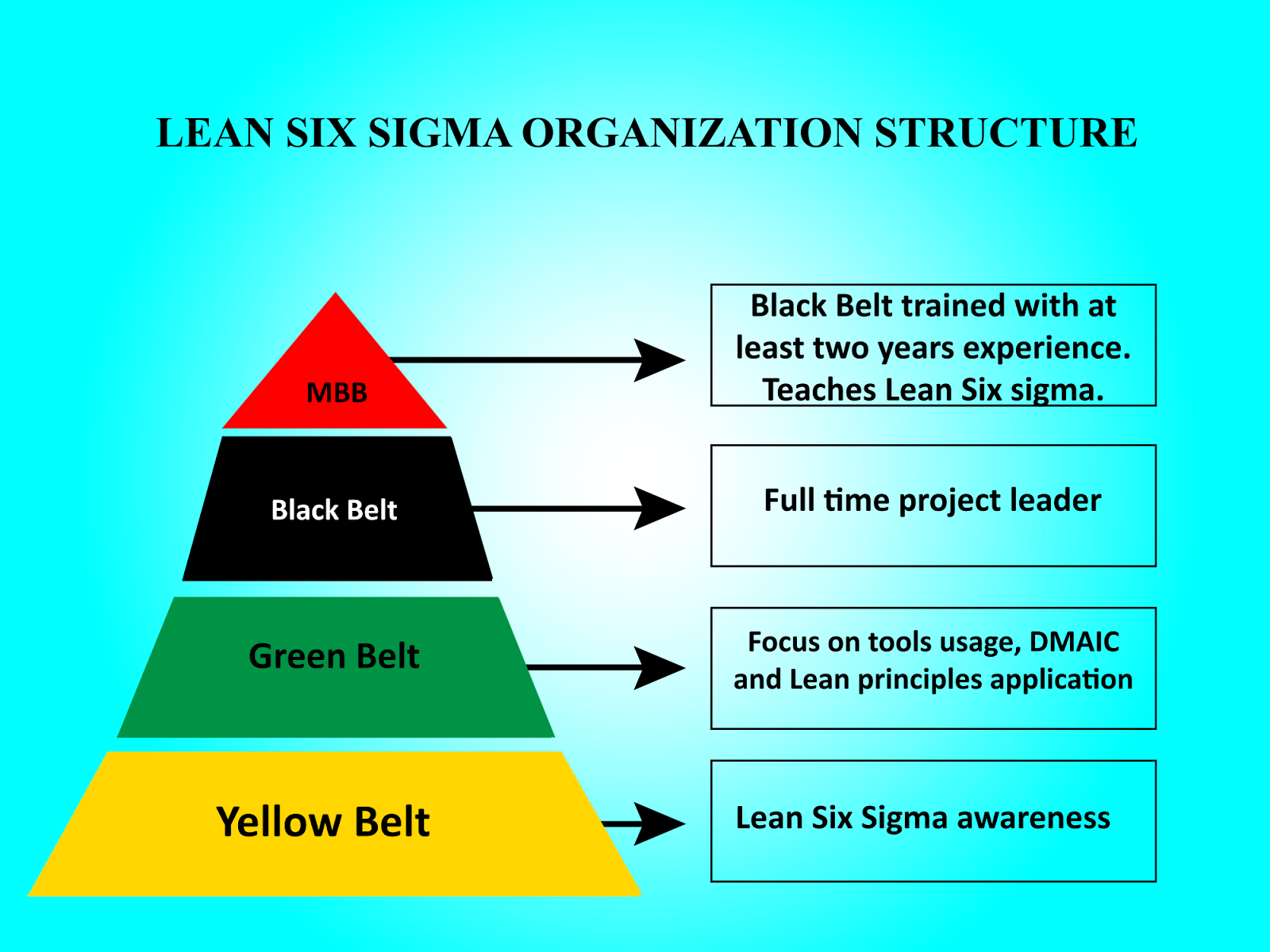

Changes in the way things are done are often the best way to eliminate waste. This can be achieved through a project management method, such as Lean Six Sigma, or simply changing the culture of your workplace and making sure you have the right tools for your job.

Many businesses still have their processes set up in a way that makes it difficult to identify and fix any wastes. This could be due to poor planning and training. This can also be caused when the right people are not used for the job.

A common example of this is people tagging onto multiple tasks, sometimes without the required skills or capability to do each task correctly. This can result in a lot of wasted time and money on tasks that could have been automated.

You can identify and eliminate any waste easily with the right tools. DataMyte's Digital Clipboard is one such tool. It is a powerful and simple to use checklist that will quickly identify areas in your workplace that could be causing waste.

Who Identified the 7 Wastes?

The 7 Wastes is a framework used by the Lean experts at Toyota to identify and eliminate unproductive manufacturing practices. This simple acronym was created by Taiichi Ohno (the father of Toyota's production systems), and has helped organizations drastically improve their efficiency by eliminating waste.

The seven wastes are Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing and Defects. The first six can be easily identified and can be quickly removed if the process is redesigned. The last one, Defects, can be a real challenge to tackle as it's easy to overlook them due to tradition.

To achieve world-class efficiency and profitability, it is important to eliminate these wastes. When these wastes are identified and addressed quickly they can help an organization to grow and thrive without breaking the bank.

Wood wastes can be used judiciously to reduce energy consumption and provide a sustainable and viable source for revenue for timber companies. This is especially true for developing countries, where the use of wood waste can significantly reduce the amount taken from the forest and the negative effects on the environment.

The best way to identify the seven wastes is by taking a step back and looking at the entire production process from the perspective of the customer. Engaging frontline workers is also important. They should be able to offer suggestions on how waste can be reduced or eliminated. This will help to build a culture of continuous improvement among the entire team and it will be easier to maintain a high level of productivity.

What makes TIMWOOD identification so important?

TIMWOOD stands for Transport Inventory, Motion, Waiting and Overproduction. Its origins are attributed to Toyota, where it was used as part of their lean manufacturing process. Using this acronym will help your safety manager identify and implement the necessary changes to make your workplace safer.

Aside from the obvious benefits of using the TIMWOOD system in your workplace, identifying and removing a few of the wastes is sure to improve productivity. The TIMWOOD acronym is an easy way to identify any potential bottlenecks before they become major headaches for your employees.

By the same token, the TIMWOOD system can be incorporated into your quality management plan to ensure that you are on top of your game at all times. You can easily improve your bottom line by using a robust, easy-to-use software solution. Contact DATAMYTE to learn more about our comprehensive quality management solution for your business. Our team of experts is happy to assist you. You can also check out our blog for more helpful tips.

What are the 7 Wastes

In Lean, waste is any activity that does not add value to the customer and costs the business money. To ensure that all of your processes are fully aligned with the customer, and to create a seamless flow of value to the end product, it's essential to eliminate waste in every step.

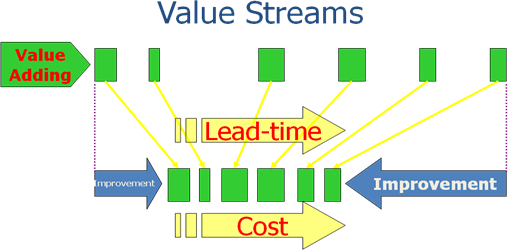

There are several ways to identify waste in your organization, but one of the most effective is using a visual standard map, also known as VSM. This process map helps you identify the most common sources of waste in your business and then helps you identify where you can make changes to remove them.

The VSM will help you identify the following 7 wastes: Transportation, Inventories, Motion, Waiting, Overproduction, Overprocessing and Defects. These seven are common in most businesses and can all be easily eliminated if they are identified and addressed.

Transportation: This is the movement of products and equipment from one location to another. It is a waste of time and space because it takes up space that could be used for more goods. It can also be costly and cause damage to the materials being transported.

Inventories: This can include extra stock that is not for resale or excess inventory that is taking up storage space. Excess inventory can lead to longer lead times, damaged or defective items, and it can also tie up valuable working capital.

The Comprehensive FAQ Guide on TIMWOOD: The 7 Wastes of Lean Manufacturing

What is TIMWOOD?

TIMWOOD stands for the 7 Wastes of Lean, which is a framework created by Taiichi Ohno, the father of the Toyota Production System. The seven wastes include Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing, and Defects. The purpose of TIMWOOD is to help organizations identify and eliminate waste in their business processes, improving efficiency and profitability.

What are the 7 Wastes of Lean?

The 7 Wastes of Lean are:

Transportation

Inventory

Motion

Waiting

Overproduction

Overprocessing

Defects

What is the purpose of TIMWOOD?

The purpose of TIMWOOD is to help organizations identify and eliminate waste in their business processes. By reducing waste, organizations can improve efficiency, increase productivity, reduce costs, and make their workplace a better place for employees to do their best work.

What is the best way to identify the 7 Wastes?

The best way to identify the 7 Wastes is to take a step back and look at your business processes objectively. Creating visual boards that highlight the seven main wastes can help make informed decisions about resource allocation and demonstrate your commitment to improvement. Another useful tool for identifying waste is DataMyte's Digital Clipboard.

What can cause waste in a business?

Waste in a business can be caused by poor planning, lack of training, incorrect allocation of resources, and resistance to change. To reduce waste, it is important to eliminate unproductive practices and use the right tools for the job.